Gulun, a Chinese shoemaker has longer history than most Chinese brands which have higher popularity. I bought one pair in 2019, and I still agree with the aesthetics today. Although the upper design is a bit of a stretch. The price is super attractive.

Mr. Pan was born in Chongqing, who have been immersed in Wenzhou shoe industry for nearly 20 years. He moved the workshop from Wenzhou back to their hometown Chongqing in 2021, and the craftsmen all followed.

I thought this move is to reduce costs, but later I learned that it was just Mr. Pan wants to live in hometown. That the craftsmen were willing to go with him shows that he is a very successful person with high integrity.

Mr. Pan is shy, and he speaks softly.

Thanks very much for his openness, allowing me to fully see the craftsmanship of Gulun.

We follow the production process.

Leather Stock

After many years of trial, leather options are tightly controlled, and from a production point of view, it should be considered a good state.

Of course, black ones make black shoes, and crust leather for non-black shoes. The second half of the sentence is not nonsense, and it means that light colour shoes are all hand painted.

Judging from customers’ feedback, crease is fine. The gloss of black leather is high.

This leather is used as a heel lining. Regarding heel lining, there are smooth leather and suede option. Smooth leather gives a better texture, and suede can provide more friction so avoiding heel slippery.

The suede leather specially selected by Gulun is quite durable.

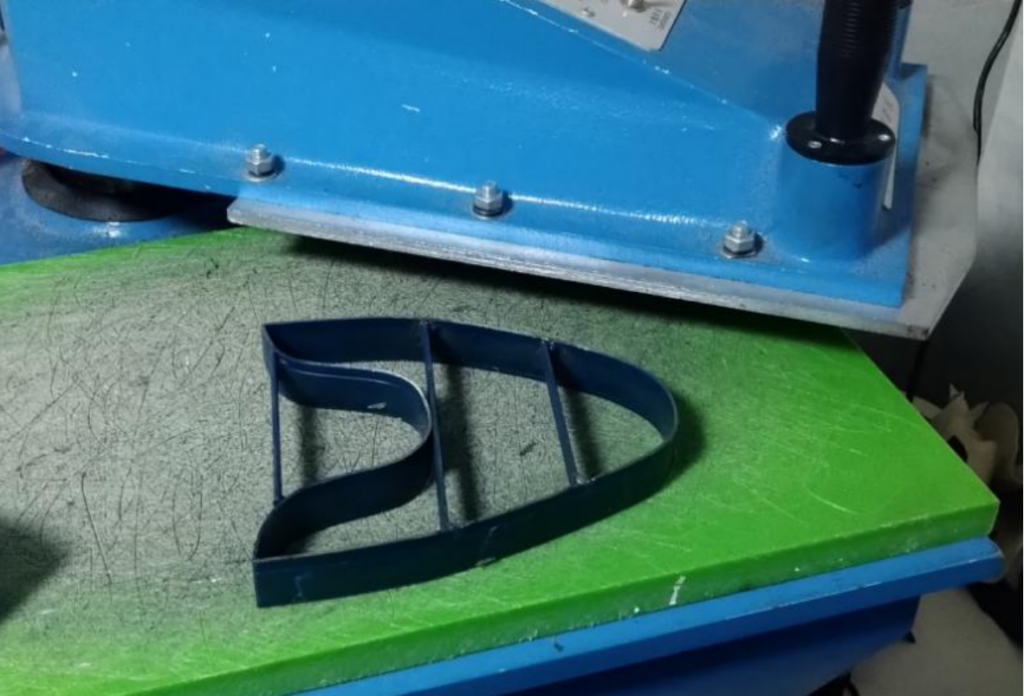

Clicking

The so-called part is to cut out the leather piece that needs to be sewn on the upper according to the style. Originally, clicking in Gulun was all manual, but now it is also improving efficiency, using a small press and mold to carry it out.

Mr. Pan felt that this was more consistent, and the probability of leather tearing was also reduced.

Since the style of Gulun is very mature now, fortunately there are not so many molds.

Upper sewing

This is a very good example of an Adelaide Oxford.

It’s also one of the best sellers from Gulun which imitates St. James from Gaziano & Girling.

This job normally is done by women.

Because Gulun has been making shoes for so many years, Mr. Pan is very familiar with where shoes are easy to break, so the craftsmanship also targeted there more.

For example, the double-line reinforcement of the inner lining.

The double line at the heel is seen more on high-end shoes. You can observe whether your shoes have this elements.

Lasting

This is to fix the sewn upper to the last and then tighten the leather. Factories use machines with bandages, and many workshops in China and Gulun are hand lasting.

Pull the leather with a special tool, tightly, and fix it to the last with nails.

Hit with a hammer to make the leather fit better on the last.

Lasted upper looks like this.

The sole looks like this. When the upper is stretched, the midsole is already fixed on it.

Speaking of Gulun shoe lasts, please have a look.

Lasts filled up two walls. Mr. Pan told me that there are 19 lasts in use at present. I said it was too much, and he said that there are four best-selling ones.

From left to right, A, B, C and D lasts. Last A is round toe, last B hard chisel, last C pointed round toe and last D soft chisel. The width narrows sequentially from left to right.

Handwelted

Sew the midsole, upper and welt together.

Filling cork

There is some debate about the filling content. Its purpose is that after wearing, with the pressure of the foot, cork will gradually fit the shape of the sole, so that it is more comfortable.

But from the example of destructing shoes, the distribution of cork is not so ideal, because the pressure in some positions is too large, and cork is completely squeezed to the side.

In addition to cork filling, there are also thin plates made of pressed cork, but this essence is the same.

Cork is filled up.

The front is not very visible, but if you change the angle, you can see the waist arched, and after sewing the bottom, you can see the effect of fiddleback waist.

Underneath the cork, from the waist to the heel, there is also a metal strip called Shank.

Sole sewing

Gulun’s outsole is fully hand-sewn, it is real handmade shoes.

First glue the outsole, and then, because the edges of the outsole will protrude a lot, it is sanded.

The width of welt and retraction at the waist are basically determined at this step.

If you don’t do things very carefully, you would like to keep stitches away from upper. But the closer, the shoes look more refined. This is the most important point of this process.

Look at the grinding on the waist.

The grinded shoes were handed over to the craftsman who sews the outsole.

Gulun has open channel and close channel sole options. process. This pair of masters made the dark line.

First cut a layer of the sole from the side with a special knife.

Pull it open, and this layer will be cocked. Then use the groove tool to make a circle of stitching grooves, which are no different from open channel bottom.

Then there’s the process of hand sewing.

After sewing, it looks like this.

Stitch density is not high, but the distance between stitches and upper is well controlled. This step does not add fudge on the welt.

Look at the finished shoe, the fine fudge, and because the stitching is very close to the upper, the visual sensation is completely attracted by the fudge. Then look at the waist, in this place, the advantages of hand-stitched outsoles are revealed.

Attach heel bottom

After the sole is sewn, the heel is glued on. Wooden heel lift is chosen considering the cost. Compared with the leather heel, it has better firmness and good cushioning, but the comfort is inferior.

It can be seen that the heel that has just been installed is a lot protruding, so it is also necessary to grind.

Grinding is complete.

It is very flat and clean, and the distance from heel upper to heel bottom is closer than that of many factory shoes. I think this distance has a great impact on aesthetics.

There is a slight Cuban heel element, and this angle is just right.

Finishing

This is the step of polishing, glazing, and coloring the sole. I didn’t take a picture, and Gulun’s signature black and red gradient sole was done in this step.

Let us have a look at its best sellers.

Wholecut oxford.

Summary

Mr. Pan is a mainstay of the industry, and his understanding of products and production is deep enough, and there are also improvements in technology. Gulun style is definitely traditionally classic. This price, of 95% handmade shoes is rare.