When people talk about leather manufacturing, they think most about tanning process, however there is another step that is extremely important, surface finish.

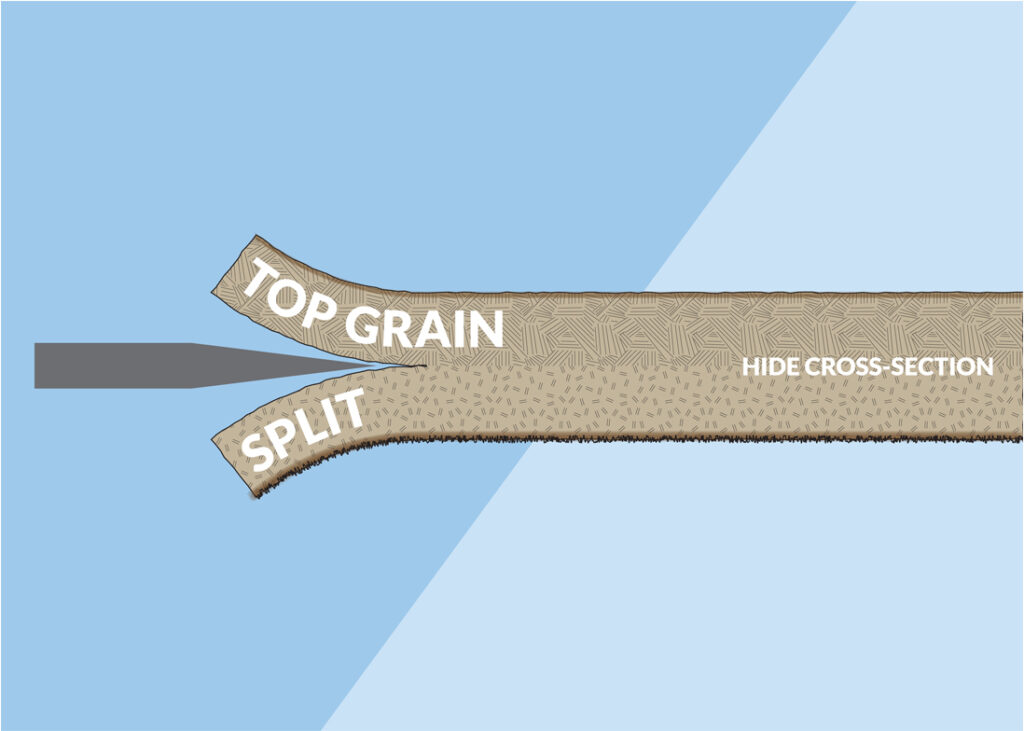

First of all, the different grades of leather, such as top grain, split and even the sanded leather we are talking about are all done in this process rather than tanning.

The main processes here are layering, polishing, embossing, coloring and oiling and waxing.

The dyeing process includes drum dyeing, spraying, brushing and dip dyeing.

The next step is to add oil and wax to the leather to lubricate it and enhance its softness, strength and waterproof ability.

In this step, it is necessary to dry the leather to about 14% moisture.

For places where the environment is too dry, it needs to be humidified to 20% water content, and then stretched and softened.

The last step is to coat the surface to make it have additional wear resistance, crack resistance, peeling resistance, water resistance, heat resistance and cold resistance.

This is when the coating or film is applied on the surface which we dislike very much.