Does Weritas custom service count as bespoke? I believe it is a question many people are curious to know.

This pair is a very great example to examine.

Let us start.

Last

When we choose a bespoke shoemaker, most of the time, we recognise his last aesthetic, and we want a pair of shoes that have the flavour of his/her.

Of course, the vast majority of bespoke shoemakers are not in the habit of pushing their customers out, for example, if you want Gaziano & Girling to make a big round toe, the kind so round that Tony wants to vomit, you can get what you want, as long as you have the ability to pay for it.

With Weritas, I had a very clear last preference, so I forced the shoemaker to obey my order.

The process of customising these shoes, which has been documented in a previous post, was modelled by me on the lasts of a pair of Henry Maxwell shoes, which I had Weritas mimic.

There were three revisions in between. Surprisingly, the final product, apart from absorbing the feel of those Henry Maxwell banana lasts, has become the ultimate form of my last aesthetic.

Probably a lot of people would say, ouch, big round toe, short and fat.

This angle already smacks of Edward Green 202 to some degree, but don’t hurry.

May I ask: “Is this toe really big?” I think the toe is actually smaller than Edward Green’s 202.

At this angle, it’s a bit of an egg toe.

So to summarise, my last aesthetic is short and banana shape.

The purpose of the Banana Last, in my case, is probably weighted 4 to 6 in favour of aesthetics and functionality.

Aesthetics is somehow subjective.

Although my feet are thin, my little toes are particularly prone to rubbing, and the Banana Last solves this problem perfectly.

Pattern

A boring Cap Toe Oxford.

I’m certainly not saying there can’t be design and innovation in this timeless classic style, it’s just that with this pair, I only cared about the last, not the design.

Leather

Plum museum calf from Italian tannery Ilcea.

I wanted this leather and colour because I unboxed a pair of Alfords from the John Lobb Prestige line and thought the colour was so textured, and then I’ve been particularly fond of wearing red lately.

The leather performance is fine, but the plating has a slightly heavier film feel.

I’ve had the pleasure of experiencing John Lobb museum leather shoes in early days, and the crease finesse and film feel is indeed much better.

This pair performs at a moderately high level.

Craftsmanship

First we look at the finish of welt and stitching on it.

You can take high marks for the stitching performance. Dense enough, neat and then also particularly close to the upper.

But in terms of this performance, you can’t lose with Gaziano & Girling, not to mention John Lobb.

The welt finish is the way we’ve seen it done quite a few times in this country, tilting the press teeth.

The waist of the sole is made to be bevelled.

It’s here that we can see that the handmade feel of this waist is just about non-existent compared to those “real” bespoke ones. It’s just this rounded bulge achieved in a relatively industrial way, and the aesthetics are lacking.

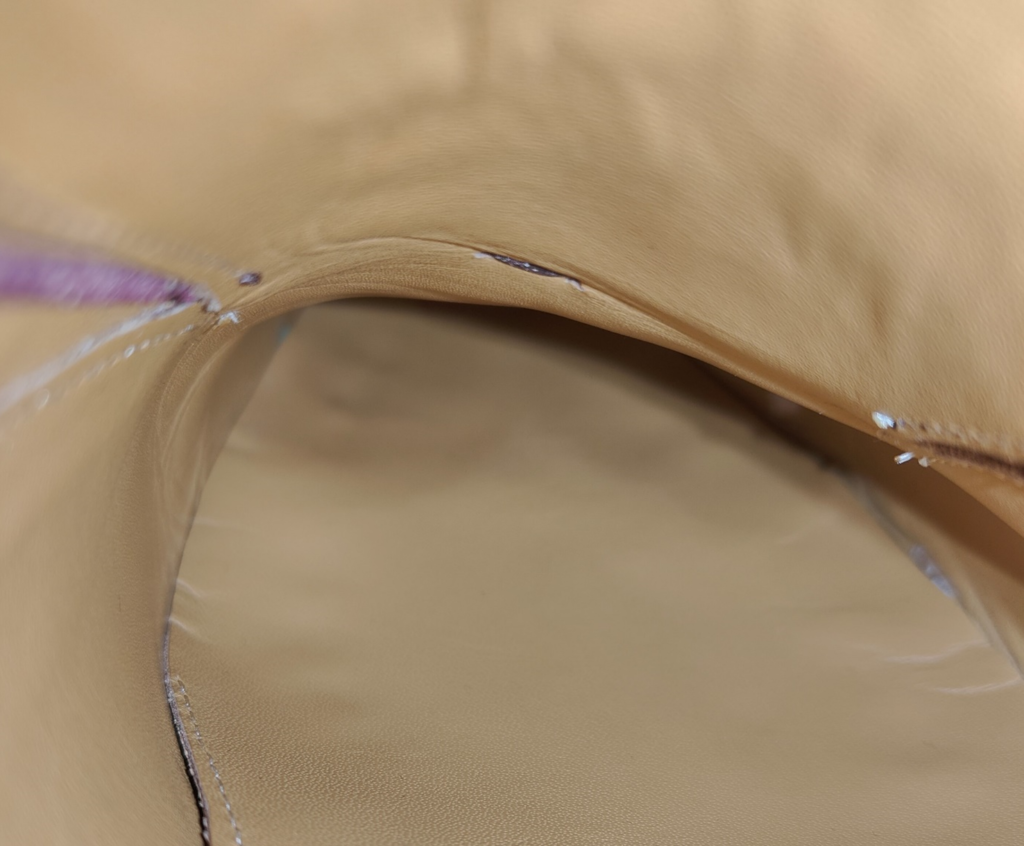

This place, again, is a point of difference from the traditional handmade bespoke.

At first glance, it seems like the stitching just isn’t close enough to the upper at the waist of the shoe. It could be a bad machine stitch there, right?

Yes, but that is only part of the reason.

The other reason is the gap between shoemaking ability and last making ability. My arches are not very high, but they are quite pronounced, so Weritas’ custom foot moulding captures this feature in its entirety, and my lasts, which have a very pronounced inward tuck, are so well supported by the upper however they are not fully hand stitched. The upper is well lasted and has such a good arch support, but when sewing, it is not a fully handmade operation, that’s why there is this gap.

In fact this is a distance I’ve seen on some ready-to-wear shoe brands, but the last shape of those shoes, or the inward arch of the foot, is much lower than my bespoke pair.

Heel Lasting

This is one of the details of shoemaking that I love to see. The most perfect I’ve ever seen is on a couple of European fully customised shoes, Henry Maxwell, George Cleverley, Maftei, not just when there’s no noticeable step between the heel of the upper and the heel of the sole, but even more so when the heel is polished to smooth out the curvature of the heel.

This pair of Weritas customised ones should be considered high standard in machine-made shoes.

Details

One of the designs that I don’t really approve of Weritas is the full sock lining.

When we look at most shoemakers, they are with half sock lining. What you step on in the forefoot is the midsole, that vegetable tanned leather. The advantage of this is that the vegetable tanned leather can directly absorb the moisture of the foot, the foot feels dry and comfortable. In addition, leather shaping effect is good.

The full sock lining of Weritas is made of leather on top and foam underneath.

Jimmy, the shoemaker behind the brand explains that most of the customers who are new to welted shoes do not want to wear shoes with hard soles to begin with. This insole is used to provide a soft foot feel.

This I can understand, but I still have two concerns, the first is the dry foot feeling, the second is the foam material, then the midsole shaping effect is not able to play?

For the moulding concern, it’s true that I was overthinking it, and it does still work. But the dryness, in my opinion, is really less than a vegetable tanned leather midsole.

Conclusion

I don’t think of this shoe much as bespoke, but if you look at it as a Ready to Wear shoe with bespoke lasts, and the last is arguably unrivalled, they are almost perfect!

This is my favourite last in the whole world ever.