I believe that people who have just come into contact with Goodyear shoes will definitely browse a large number of goods online, and then they will find that the prices range from a few hundred to ten thousand.

Let’s confine our discussion to machine Goodyear shoes and exclude hand-made shoes. So the price difference caused by labor can be ignored.

First of all, we have to admit that this price difference mainly comes from the brand, not the cost. But the product itself, there are also many cost differences.

At the very least, a person who thinks that 1000 RMB is almost the starting price of Goodyear welted shoes is very shocked to suddenly see a pair of Goodyear shoes with 400 yuan.

How is this done? Simply don’t make a profit?

The answer is because you don’t know enough information. In other words, you don’t know enough about the product.

To put it another way, when it comes to suits, there is a lot of information on the Internet, half canvas vs full canvas, which makes consumers feel that they are particularly familiar with them, and then they find that when they are all full canvas, how they charge from 2000 to more than 20,000 per piece?

Is it also because of brand value? Part of the reason, maybe not a low proportion, but it is also related to labor cost, because there are also mechanical and manual jobs in canvas linings, and there are many manual levels.

This is the missing information.

As a media, I just want to make information more circulating and transparent. On the one hand, I want consumers to make better choices; on the other hand, I want businesses to compete more orderly.

Speaking of shoes, I don’t make shoes. I dare not say how clearly I know the inside, but there are some points that can be passed on to everyone.

Lining

Everyone may think that Goodyear welted shoes are high-grade products, so the lining should be leather, but in order to save costs, fabrics can be used. The fabric can be cotton canvas or even polyester.

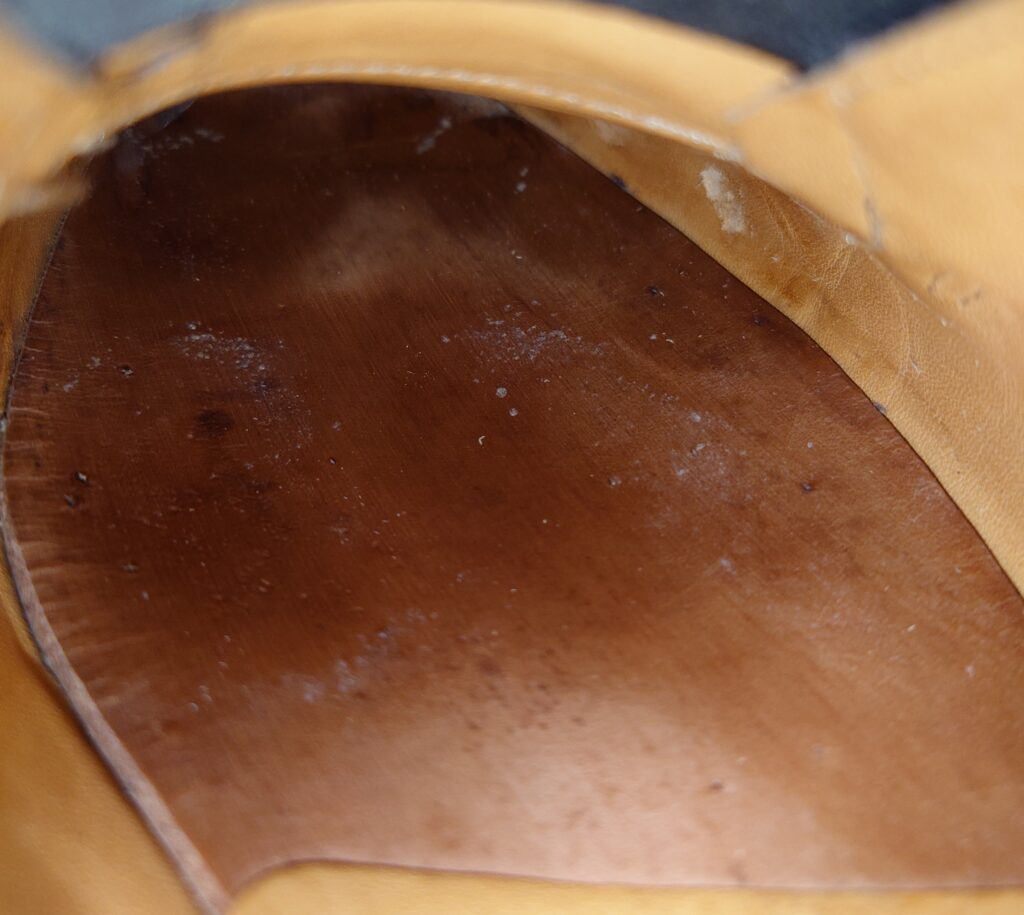

Midsole

There is a component that everyone will default to vegetable tanned leather, but low-priced shoes use fiberboard or even cardboard. I am very disgusted with latter components, because it has a great influence on the wearing experience, and it has no leather molding effect, and the moisture absorption (perspiration) effect is almost zero.

Heel lift

On the market, there are quite few shoemakers stack layers of leather to build the heel, and many of them use wood. Similarly, layers of stacked leather will have a better shock absorption feeling.

Then there is a detail, which can even be called critical theory. Isn’t there a piece of rubber in the heel? The bigger the rubber leather, the lower the cost of heel, and the worse the grade of shoes. The smaller the rubber leather area, the more exquisite it is.

There are many differences about wax, pigment and glue.

Back to the biggest cost of shoes, upper leather, everyone has a little idea now, such as Ilcea Museum Calf, Zonta Nevada and C.F.Stead Janus suede, but there are actually many good leather from not so famed tanneries which is also worth developing.