I love visiting workshops, because I may be better suited to job learning than learning from books, learning by doing, and learning when I put on hands on.

I have a certain affection for welted shoe industry. This feeling is not triggered by shoes, but after getting to know so many practitioners. Whether they are in this industry for a long time, it can be said very responsibly that they joined this industry solely because they like this product. This is actually no different from enthusiasts, everyone comes together because of what they like.

Last month, I went to Oct Tenth’s new workshop, and this time Wiracetas also moved to a new factory, and still in Taicang. This site is not bad, originally a state-owned pen parts factory.

The equipment was moved over, and then the station was adjusted to be more in line with the flow of production process.

Here is a little mention of Wiracetas, 1) the selling point of this brand is MTM and foot mold customization. 2) handwelted construction with outsole stitched by machine. 3) it mainly uses museum calves.

This brand is not to be a price challenger, simply look at shoes and craftsmanship, 2500 RMB is very acceptable for its handwelted construction. However it focuses on those who have special feet and cannot find suitable shoes. This is the core competitiveness and differentiation.

This is the current panorama of the workshop, from clicking, step by step, to the final finishing, the shoes are boxed out of the factory, smooth flow.

Entering the workshop door, there is such a shelf, on which are the customized plaster foot molds, which is the core selling point. When I glanced at it like this, I could see the thumb turned outward, very small feet and extremely fat feet.

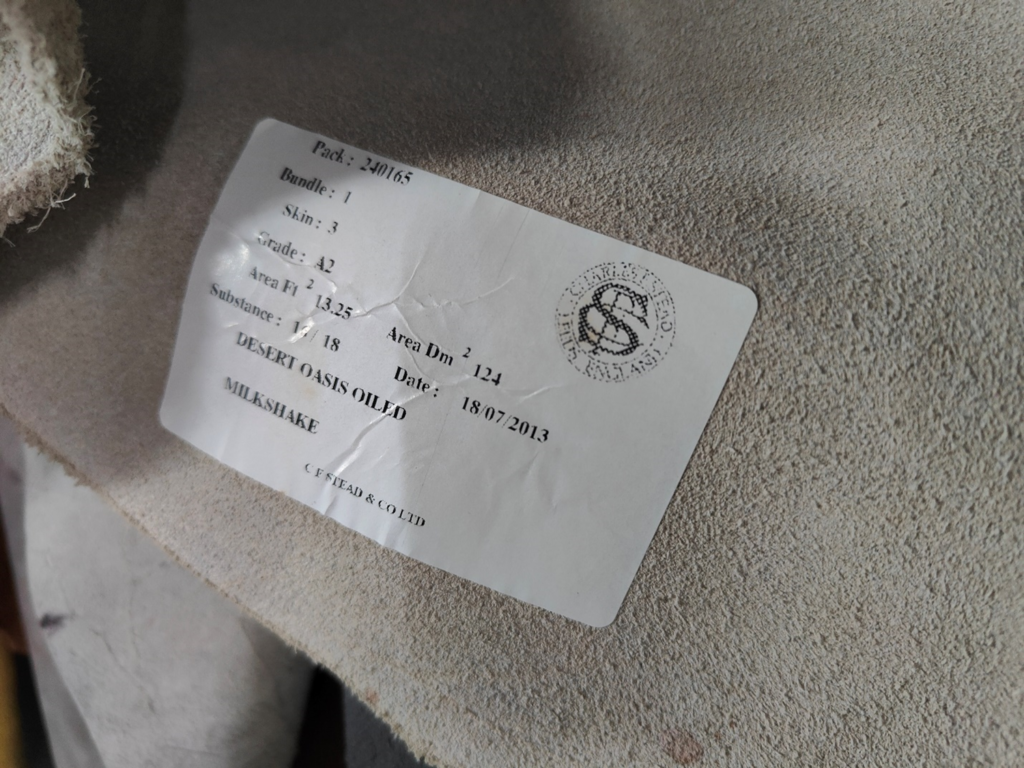

Opposite to the first station in the panorama is the leather warehouse. Because Wiracetas is in MTM business mode, leather stock are limited.

Leather, all used by mainstream tanneries, such as this should be Charles F. Stead’s Repello series of anti-suede.

The most important and recommended to customers is museum calf from Italian tannery Ilcea. The colour option is extensive.

This is the inside of the lining, the right side is the upgraded product, from the flesh surface, you can see that the right side is noticeably more delicate and firmer.

This is the side where the lining touches the foot. Apart from being able to tell that the pores are clear, I have nothing to judge.

As for the lining, although I have done a lot of looks, my feet do not seem to have a clear feeling, maybe my feet are too rough.

We come to the first step, clicking.

In the promotional films of European and American brands, there is few shots about clicking because most brands use machine to arrange the shape and press. Only high-end brands, or Italian handmade workshops shoot this paragraph as the craftsmen are cutting the leather.

The point of clicking is not manual or automatic, but to do it thoughtfully so that the best position can be selected to be the most important Vamp area. I came across the belly at the ankle on Antonio Meccariello’s shoes, and I think it is okay as long as the Vamp is delicate because it isn’t very visible.

The next step is to sew the upper of the shoe, and the shapes cut in the previous step are spliced together to form the layout of the shoe, including attaching the lining.

Pictured here is Pie Crust sewing method led by Edward Green.

The craftsman is making the midsole, that is, grooving on it, ready to be sewn together with welt, an important part of the so-called handwelting construction.

Why the midsole edge should be shoveled thin, I don’t quite know.

The craftsman who handles midsole is also the one does handwelting. When I was there, I did not photograph this step, including the midsole wall lifting and stitching.

This outsole has been sewn and the sole is being grinded.

The delicacy of the shoe, such as the welt width, how large the gap is between the heel and the upper, is determined at this step.

Finally, there is finishing including knurled welt, finishing of the heel, coloring of the sole, and waxing of the upper. The picture is waxing and polishing with a machine.

On the other side of the room, there are machines.

And what occupies more positions is the basket of shoe lasts. I have also seen a large number of shoe lasts in shoe factories, but here a shoe last represents a customer, which is still very impressive.

Summary

That is all the process of Goodyear shoemaking. The process of Wiracetas is very common, handwelting construction is also practiced by many workshops in China. The final presentation of shoes, I think, comes from the design, including the last, layout, brand details, and on the other hand, in the degree of finesse of production. However, the production process determines the quality of the shoes, which requires a large amount of market feedback to be worn for a long time.