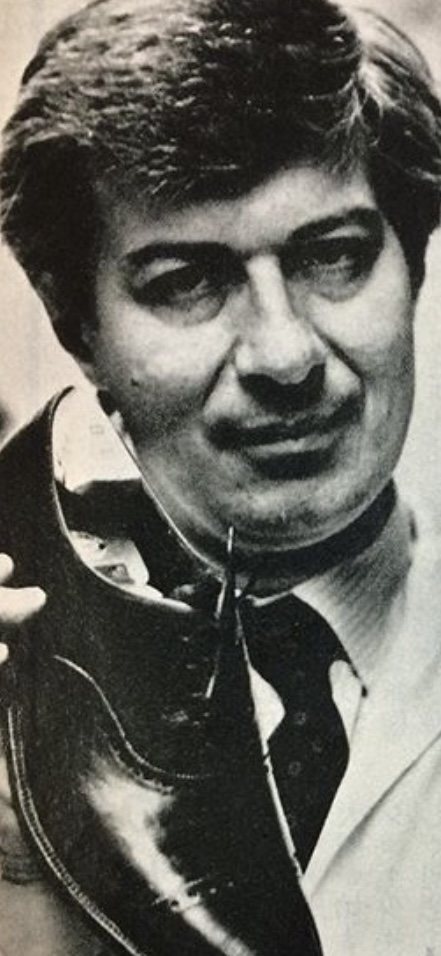

Adam Law is a wonderful English bespoke shoemaker who trained in George Cleverley as last maker for many years, now he sets up his own atelier and offers quite iconic and interesting bespoke shoes.

It is a great honour to have the opportunity to talk with him.

Could you briefly introduce your self?

I’m 43, a shoemaker, and I’m running my own business.

I took a foundation diploma in Art and Design, then went on to study Fashion and Textiles at Brighton University.

What is your career before being a shoemaker?

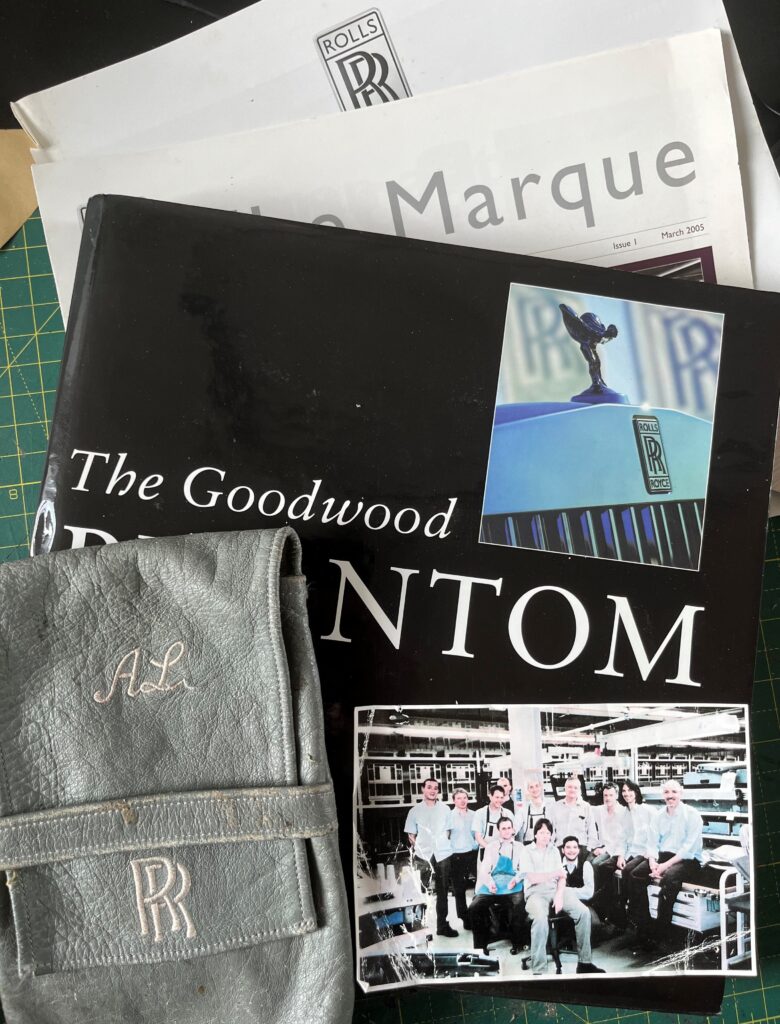

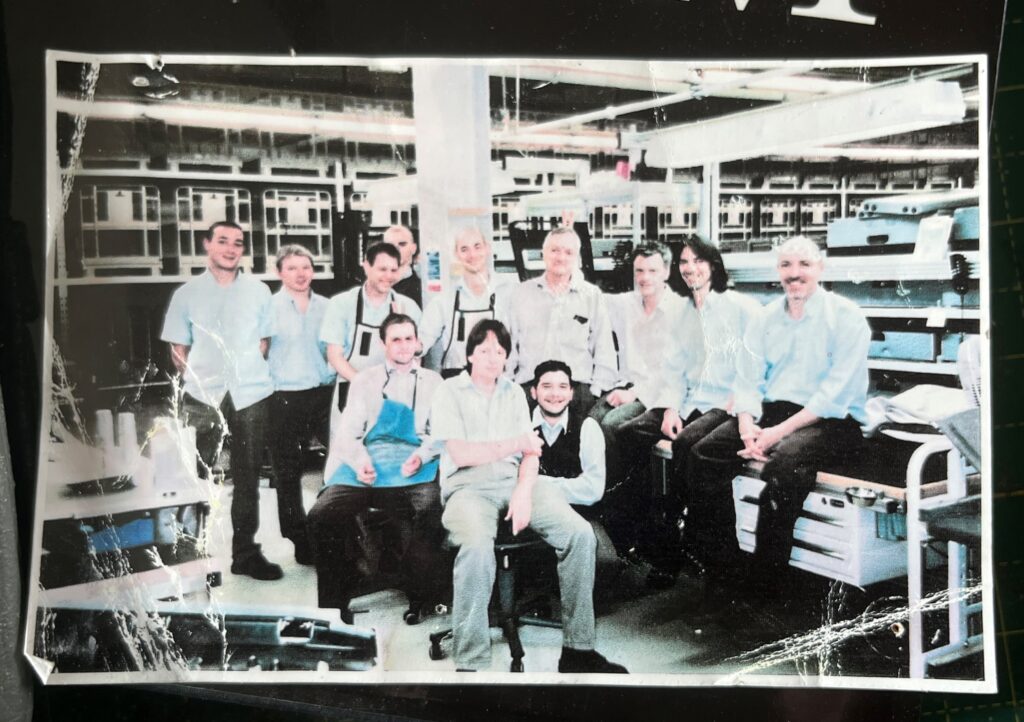

After graduating, my first job was working on leather interiors for Rolls-Royce—nearly two years making the Phantom. Beautiful work, but every car was the same, just in a different colour.

So I left, intent on getting into shoemaking.

What is the difference between working on automotive interiors and bespoke shoemaking?

When I worked at Rolls-Royce, the focus was on precision and finish, everything had to be immaculate, so it was a good learning experience. They used Friedenburg skins, very good quality, but very different to what you would use for shoemaking. It was all about surface and uniformity, polished, controlled.

With shoes, it’s more intimate, more sculptural. Leather for footwear needs life in it, it’s got to flex, age have polish applied.

They would call their cars bespoke, but really, you were picking colours. In shoemaking, I could make nothing but black calf oxfords for the rest of my life, and every pair would still be different. That’s the difference, one is decoration, the other is craft.

What was your journey at George Cleverley? What was your position, and how did that evolve?

I started as an apprentice, I wanted to be a last maker and I ended up as managing director after nearly 17 years. My titles changed over time, but it was a small team and the learning never stopped. You take what you’re taught, and then you refine it, test it, question it. Everything I learned, I put straight into the work.

Who do you most admire in bespoke shoemaking?

John Carnera.

I’ve worked with him for years. He’s been making shoes for over 70 years and still at it. He’s got that old-school knowledge that only comes from making thousands and thousands of pairs. There’s no short version of that, no tutorial, no shortcuts.

When did you know it was time to open your own atelier, and why?

It crept up on me slowly, then all at once. I’ve always had a DIY attitude, make it yourself, build it yourself. Eventually, I found myself unhappy and knew I needed to steer the ship myself. I wanted to make what I believed in, and be responsible for my direction.

Your last is more exaggerated than George Cleverley’s chisel toe. How did your style evolve?

Right now, I’m making orders, so I build what my clients want. But I’m developing my own range. My eye goes towards dressing the foot rather than just accommodating it, shaping it, refining it. I want the shoe to have style.

West End style emphasizes exquisiteness. Do you think Adam Law follows that same tradition?

I follow the three core principles of true bespoke: made by hand, to your measurements, in your style. The west style uses these, but there is a little more, in the way that somethings are finished or executed that I like.

We see more independent shoemakers in the UK. Is this a trend? What’s the difference between going to a house or going to someone like you?

Definitely—it feels like a bit of a renaissance. In the ’90s and 2000s, the big firms swallowed up a lot of the smaller makers. Now the independents are finding their voice again.

With a house, you get brand recognition, a bricks and mortar shop, But with an independent like me, it’s more personal. I’ve got a smaller client base, so I can take the time to understand your taste, your quirks, what works and what doesn’t. It becomes a conversation, not a transaction.

Which leathers do you recommend most?

I like Annonay—it’s got a beautiful quality and it handles well, but it depends on the shoe.

Upper leather for shoes or boots are a balancing act. A big chunky Danite sole with a storm welt needs something robust up top—2mm thick, maybe more.

But if I’m making a town shoe with a 1/4” leather sole, I’m after something closer to 1.2mm. You buy leather by thickness, so you need to understand what you are making to find or recommend the most suitable leather.

Where do you attract customers?

Mostly through my website or Instagram. People reach out. It’s all quite organic.

What’s the plan for the near future?

Keep going. Grow the business slowly and honestly. I’m developing samples now, and planning more travel, more fitting trips. Eventually, I’ll have a small collection that evokes classic and can be the mainstay of my offering.

Location, Price and Delivery Time

I work out of London and have access to a shared fitting room in Mayfair.

My shoes start from £3,500.

Lead time is around 4–6 months, depending on location and fittings.